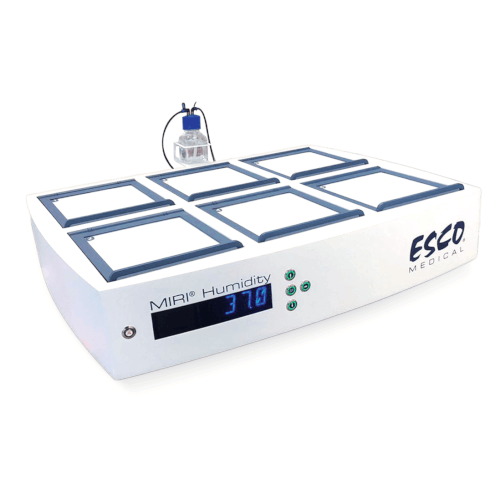

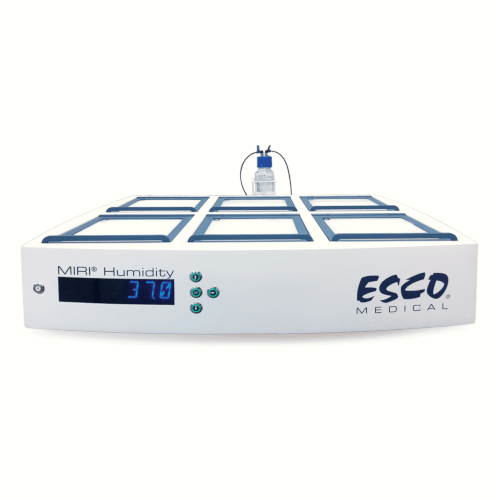

The OKOLAB Tri-Gas Mixer is a versatile and precise CO2-O2 controller, engineered for optimal control over gas concentrations and pressure. The system mixes CO2, air, and N2 to achieve desired concentrations from 0-10% for both CO2 and O2, and it can manage controlled pressure within the range of 0-2 barg (0-30 psig). An adjustable knob on the embedded pressure gauge allows users to easily regulate delivery pressure.

To assure consistent composition, the Tri-Gas Mixer comes with a mixing tank that provides stability even with variable output flows. It features compatibility with any mini incubator on the market, demonstrating flexibility and adaptability to diverse lab environments.

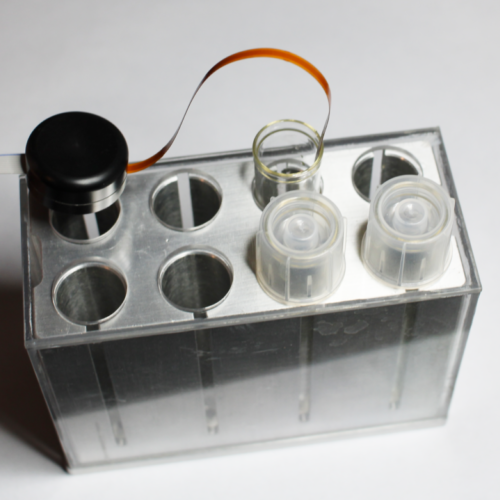

The system includes a CO2-O2-MODULE, housing the CO2 and O2 sensors, which deliver high accuracy volume concentration measurements. These sensors facilitate automatic fine-tuning of the output gas. The module is factory calibrated, with a calibration certificate included in electronic format. On-site calibration or module replacement are also options, both of which do not require the disconnection or turning off of the Tri-Gas Mixer.

An added advantage of the Tri-Gas Mixer is its self-calibration procedure. This can be periodically carried out to maintain high accuracy, using a connected calibration gas that closely matches standard working condition concentrations. This procedure can also be manually initiated if needed, and does not interrupt the delivery of gas to connected incubators.

Two configurations of the Tri-Gas Mixer are available, offering maximum output flow rates of 1.5 L/min and 15 L/min.

- Automatic switch to backup cylinder upon alarm

- On board memory for data logging

- Auto calibration with an external calibration gas

- Contact closure alarm

- Auto diagnostic procedure

- VOC-IN-BYPASS (optional) : VOC filter’s holder with bypass panel to saturate newly installed filters with CO2 before using them with the tri-gas mixture