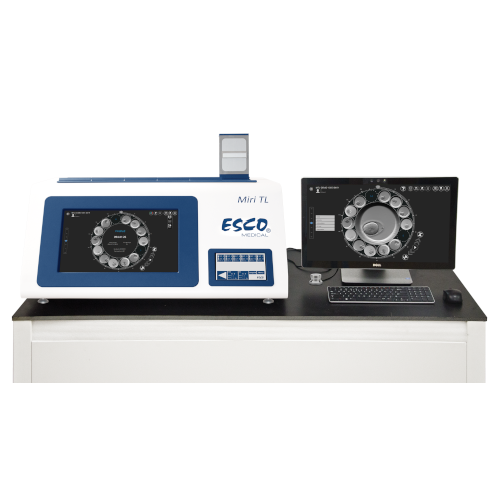

The ESCO Airstream Class II Type A2 Biosafety Cabinet is a critical piece of equipment designed primarily for applications necessitating a sterile work zone, including those that require the handling of pathogenic biological samples. It offers comprehensive protection to the operator, the laboratory environment, and the product or process within the work zone against particulates and airborne contamination.

This Biosafety Cabinet is engineered with an inflow system that safeguards the operator from potentially harmful substances. To ensure maximum protection of the samples and operator, it employs ULPA/HEPA-filtered downflow, creating a negative pressure ISO Class 3 work zone that effectively prevents cross-contamination. This both prevents airborne contaminants from escaping the work zone and protects the operator from exposure to potentially hazardous materials.

Built for practicality, the ESCO Airstream Class II Type A2 Biosafety Cabinet features a single-piece work tray and single-piece wall design, facilitating ease of cleaning and maintenance while enhancing overall durability. The ESCO Airstream Class II Type A2 Biosafety Cabinet is controlled by the Sentinel™ Gold Microprocessor controller, ensuring precise operational control and monitoring. It is also equipped with a DC ECM motor, allowing for energy savings of up to 70% and contributing to the cabinet’s efficiency, environmental friendliness, and quiet operation.

Single unit

- Certified in compliance with NSF 49 and EN 12469 standards

- Equipped with a DC-ECM blower that facilitates up to 70% energy savings compared to AC motors.

- Available in a range of sizes to accommodate various laboratory space availabilities.

- Maintains a stable and self-compensating airflow, reliably countering building voltage fluctuations and filter loading.

- Features a UV lamp for decontamination to maintain sterility within the work zone.

- Coated with Isocide™ powder to actively inhibit microbial growth, thereby promoting a safer working environment.